roughing end mill cutter diagram

Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

How To Choose The Best Solid Carbide End Mill Design For Your Application

Secondary 2nd angle 14 17 degrees Relief adjacent to the cutting edge.

. Available in Stub Standard Medium and Reduced Neck. The tooth design allows for little to no vibration but leaves a rougher finish. Roughing End Mills also known as ripping cutters or hoggers are designed to remove large amounts of metal quickly and more efficiently than standard end mills.

Cutting image by tool bit Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. You do have to use a mist coolant system to get the chips out of the slot flood coolant or oil will not work there. Side milling curved surface milling and.

It is measured from the start of the necked portion to the bottom of the cutting end of the tool. Roughing end mills are also sometimes known as rippa or ripper cutters. For use on wood and aluminium.

A standard corner radius protects the tool corner and enhances tool life in aggressive roughing applications. Wood Ruff Cutter 9. Concave Small hollow required on the end face of an Endmill.

End mill A multi-functional tool which has cutting edges on the periphery and an end face. Concave Small hollow required on the end face of an Endmill. These end mills clamp onto tool blanks to machine flat surfaces.

They are designed to remove large amounts of material quickly and more efficiently than standard end mills. End Mill and Milling Cutter Sets. Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required.

Founded in 1957 Fastcut Tool lives up to its name with Americas most extensive fast-cutting line of roughing end mills. This feature is produced by a dish angle produced on the cutter. The SS series is offered in stub standard.

The SS series 3 flute end mill remains the work horse when roughing in ferrous alloy applications. This reduces chatter and vibration which could otherwise be larger because of the jagged teeth. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM.

As the cutter rotates the tool blank creates a wide shallow cut on the face of the workpiece. This table shows end mill diameter sizes for inch metric and micro milling bits from 0005 to 1. However these cutters can cut downwards at an angle of 45 degrees or so.

Multiple teeth come into contact with the workpiece at the same time. Key Conventional and Climb Milling Properties. 5 Flute Single End w flat 45 Helix Fine Pitch Center Cutting TC Carbide Roughing End Mill Five flute Triple Crown carbide fine pitch end mills with a higher helix provides a high shear and lifts chips away from the cutting action.

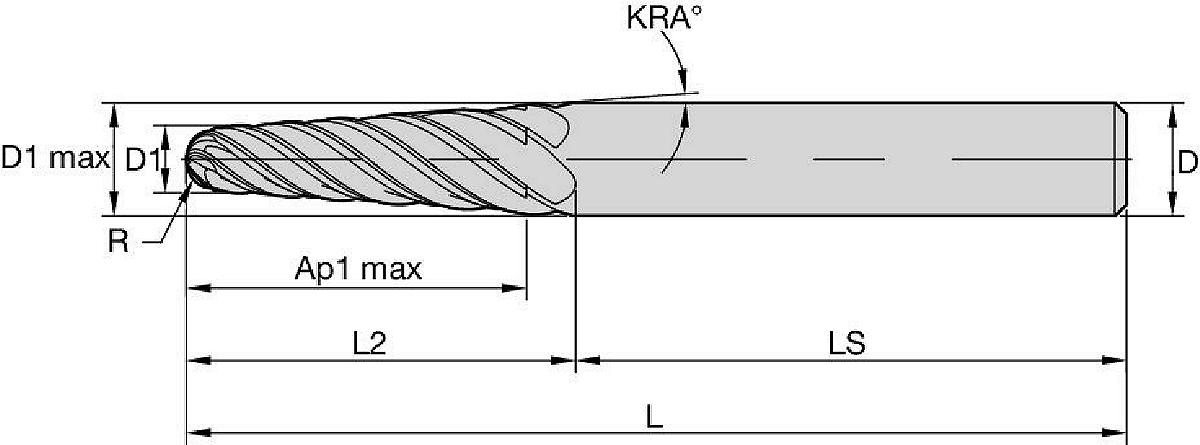

The distance between scallops is referred to as pitch. Download scientific diagram Main features of an end-mill cutter from publication. The cut bits of metal are smaller than usual and therefore easier to clear.

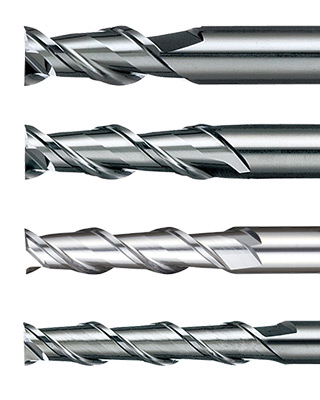

Roughing or FinishingDifferent types of cutter are available for cutting away large amounts of material leaving a poor surface finish roughing or removing a smaller amount of material but leaving a good surface finish finishing. End Mills have either 2 3 or 4 flutes per bit. Drill A tool for drilling.

Secondary 2nd angle 14 17 degrees Relief adjacent to the cutting edge. More on this Product Distributors Order Online. It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer.

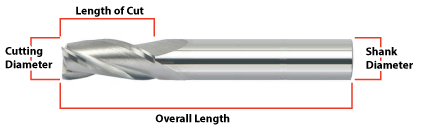

The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. Types of Milling Cutters 1. Up to 16 cash back Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations.

Involute Gear Cutter 7. This results in lower cutting pressures at a given radial depth of cut. 58 Roughing End Mill.

HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. Roughing and Finishing Capabilities. 2 and 4 flutes are the most popular.

Flutes provide an empty path for the cutting chips to escape from when the end mill is rotating in a workpiece. 2 Flute End Mills Slot drills. End Mill Cutter Cutting teeth on end mill cutters are made at its ends and periphery.

Coarse tooth roughing end mills remove large chips for heavy cuts deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application. The flatted shank can be used in a conventional holder. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep- pocket milling applications.

Slide and Face Cutter 12. Dovetail Cutter Types of Milling Cutters Are you curious to know about the types of milling cutters. Tertiary 3rd Additional relief clearance provided adjacent to the secondary angle.

Cutting edges are only on a top. Roughing endmills will take a cut the full length of the mill in a pass to cut a slot at a faster rpm and feed than a standard endmill. Roughing End Mill Cutter Related PostsEnd Mill CutterBall Mill CutterFace Mill CutterHollow Mill CutterSlab Mill CutterThread Mill CutterDovetail CutterFly Cutter.

Roughing End Mill 2. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Roughing End Mills HiTex-C 6 Flute Rougher Increased Core for Strength and Stability in Cut Fine Pitch Serrations for Chip and Form Control High Temp Alloy Specific Geometry High Temp Alloy Specific Coatings FeRx Variably Indexed Rougher Tool of Choice for Ferrous Roughing Applications Freer Cutting Better Chip Form and Control.

Roughing End Mill Cutters Shop our selection of roughing cutters for use with any End Mill Notcher that requires a 125 shank. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Arbor-Mount Milling Cutters Use these milling cutters with an arbor to make horizontal cuts.

These cutters have conical surfaces with cutting edges. Also available in PDF format to download for future reference. The roughing end mill has jagged teeth.

The Spiral-shaped cutting edges on the side of the end mill are called flutes. Ball Mill Cutter 6. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure.

These make the cutting process faster than with a regular end mill.

Endmill Design Basics Mastercut Tool Corp

Hmx 4e Hm 4e Cnc Tools Milling Cutter Solid Carbide End Mill Milling Cutters Cutting Tools Tungsten Carbide Endmill Milling Cutter Aliexpress

Xcan 2 Flute Ball Nose End Mill 4 6mm Shank Cnc Router Bit Carbide End Mill Spiral Milling Cutter For Woodworking Milling Cutter Aliexpress

End Mill An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co

The Secret Mechanics Of High Feed End Mills In The Loupe

End Mills For Aluminum And Resin Ns Tool Co Ltd

End Mills With Diameter 20 Mm For Milling Experiments A End Mill With Download Scientific Diagram

Bb Corner Radius End Mill Cnc R Bullnose Cutter Tungsten Carbide Steel Metal Router Tool 3 4 Flutes R0 5 R1 Surface Machining Milling Cutter Aliexpress

Amazon Com Accusize Industrial Tools 3 4 Fine Tooth M42 8 Cobalt Tialn Roughing End Mill 3 4 Shk Dia 1 5 8 Flute Length 3 3 4 Oal 4 Flute 1104 0034 Industrial Scientific

Flute Profile Of The End Mill Cutter Example 1 Download Scientific Diagram

Endmill Selection Guide Redline Tools Redline Tools

End Mills Cad Cam Engineering Worldwide

End Mills The Essential Beginners Guide

End Mills Milling Cutters High Speed Cobalt

Hss Roughing End Mills 5 16 3 4

End Mill An Overview Sciencedirect Topics

Differences Between Drilling And End Milling Drill Vs End Mill Youtube

Solid Carbide End Milling Harvi Iii Solid Carbide End Mill For 5 Axis Machining To Significantly Increase Output And Decrease Machining Time